Adresse:

No.233-3 Yangchenghu Road, Xixiashu Industripark, Xinbei-distriktet, Changzhou City, Jiangsu-provinsen

• Høj præcision og høj effektivitet kan opnå højkvalitets behandlingsoverflade af kobberelektroder.

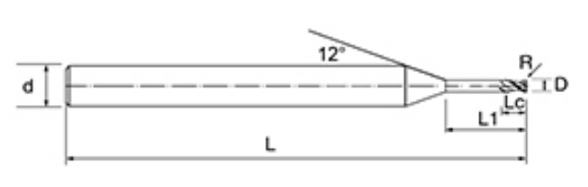

| Nej. | Diameter D | R Vinkel R | Fløjte Længde Lc | Effektiv længde L1 | Samlet længde L | Shank Dia d | Klingetælling F |

| NNX-2RSP-D0.2-L1 | 0.2 | 0.02 | 0.2 | 1 | 50 | 4 | 2 |

| NNX-2RSP-D0.2-L1.5 | 0.2 | 0.02 | 0.2 | 1.5 | 50 | 4 | 2 |

| NNX-2RSP-D0.2-L2 | 0.2 | 0.02 | 0.2 | 2 | 50 | 4 | 2 |

| NNX-2RSP-D0.2-L3 | 0.2 | 0.02 | 0.2 | 3 | 50 | 4 | 2 |

| NNX-2RSP-D0.2-L1 | 0.2 | 0.05 | 0.2 | 1 | 50 | 4 | 2 |

| NNX-2RSP-D0.2-L1.5 | 0.2 | 0.05 | 0.2 | 1.5 | 50 | 4 | 2 |

| NNX-2RSP-D0.2-L2 | 0.2 | 0.05 | 0.2 | 2 | 50 | 4 | 2 |

| NNX-2RSP-D0.2-L3 | 0.2 | 0.05 | 0.2 | 3 | 50 | 4 | 2 |

| NNX-2RSP-D0.3-L1 | 0.3 | 0.02 | 0.3 | 1 | 50 | 4 | 2 |

| NNX-2RSP-D0.3-L1.5 | 0.3 | 0.02 | 0.3 | 1.5 | 50 | 4 | 2 |

| NNX-2RSP-D0.3-L2 | 0.3 | 0.02 | 0.3 | 2 | 50 | 4 | 2 |

| NNX-2RSP-D0.3-L3 | 0.3 | 0.02 | 0.3 | 3 | 50 | 4 | 2 |

| NNX-2RSP-D0.3-L4 | 0.3 | 0.02 | 0.3 | 4 | 50 | 4 | 2 |

| NNX-2RSP-D0.3-L1 | 0.3 | 0.05 | 0.3 | 1 | 50 | 4 | 2 |

| NNX-2RSP-D0.3-L1.5 | 0.3 | 0.05 | 0.3 | 1.5 | 50 | 4 | 2 |

| NNX-2RSP-D0.3-L2 | 0.3 | 0.05 | 0.3 | 2 | 50 | 4 | 2 |

| NNX-2RSP-D0.3-L3 | 0.3 | 0.05 | 0.3 | 3 | 50 | 4 | 2 |

| NNX-2RSP-D0.3-L4 | 0.3 | 0.05 | 0.3 | 4 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L1 | 0.4 | 0.02 | 0.4 | 1 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L1.5 | 0.4 | 0.02 | 0.4 | 1.5 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L2 | 0.4 | 0.02 | 0.4 | 2 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L3 | 0.4 | 0.02 | 0.4 | 3 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L4 | 0.4 | 0.02 | 0.4 | 4 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L5 | 0.4 | 0.02 | 0.4 | 5 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L6 | 0.4 | 0.02 | 0.4 | 6 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L1 | 0.4 | 0.05 | 0.4 | 1 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L1.5 | 0.4 | 0.05 | 0.4 | 1.5 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L2 | 0.4 | 0.05 | 0.4 | 2 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L3 | 0.4 | 0.05 | 0.4 | 3 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L4 | 0.4 | 0.05 | 0.4 | 4 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L5 | 0.4 | 0.05 | 0.4 | 5 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L6 | 0.4 | 0.05 | 0.4 | 6 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L1 | 0.4 | 0.1 | 0.4 | 1 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L1.5 | 0.4 | 0.1 | 0.4 | 1.5 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L2 | 0.4 | 0.1 | 0.4 | 2 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L3 | 0.4 | 0.1 | 0.4 | 3 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L4 | 0.4 | 0.1 | 0.4 | 4 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L5 | 0.4 | 0.1 | 0.4 | 5 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L6 | 0.4 | 0.1 | 0.4 | 6 | 50 | 4 | 2 |

| NNX-2RSP-D0.5-L2 | 0.5 | 0.02 | 0.5 | 2 | 50 | 4 | 2 |

| NNX-2RSP-D0.5-L3 | 0.5 | 0.02 | 0.5 | 3 | 50 | 4 | 2 |

| NNX-2RSP-D0.5-L4 | 0.5 | 0.02 | 0.5 | 4 | 50 | 4 | 2 |

| NNX-2RSP-D0.5-L5 | 0.5 | 0.02 | 0.5 | 5 | 50 | 4 | 2 |

| NNX-2RSP-D0.2-L1 | 0.5 | 0.02 | 0.5 | 6 | 50 | 4 | 2 |

| NNX-2RSP-D0.2-L1.5 | 0.5 | 0.02 | 0.5 | 8 | 50 | 4 | 2 |

| NNX-2RSP-D0.2-L2 | 0.5 | 0.02 | 0.5 | 10 | 50 | 4 | 2 |

| NNX-2RSP-D0.2-L3 | 0.5 | 0.05 | 0.5 | 2 | 50 | 4 | 2 |

| NNX-2RSP-D0.2-L1 | 0.5 | 0.05 | 0.5 | 3 | 50 | 4 | 2 |

| NNX-2RSP-D0.2-L1.5 | 0.5 | 0.05 | 0.5 | 4 | 50 | 4 | 2 |

| NNX-2RSP-D0.2-L2 | 0.5 | 0.05 | 0.5 | 5 | 50 | 4 | 2 |

| NNX-2RSP-D0.2-L3 | 0.5 | 0.05 | 0.5 | 6 | 50 | 4 | 2 |

| NNX-2RSP-D0.3-L1 | 0.5 | 0.05 | 0.5 | 8 | 50 | 4 | 2 |

| NNX-2RSP-D0.3-L1.5 | 0.5 | 0.05 | 0.5 | 10 | 50 | 4 | 2 |

| NNX-2RSP-D0.3-L2 | 0.5 | 0.1 | 0.5 | 2 | 50 | 4 | 2 |

| NNX-2RSP-D0.3-L3 | 0.5 | 0.1 | 0.5 | 3 | 50 | 4 | 2 |

| NNX-2RSP-D0.3-L4 | 0.5 | 0.1 | 0.5 | 4 | 50 | 4 | 2 |

| NNX-2RSP-D0.3-L1 | 0.5 | 0.1 | 0.5 | 5 | 50 | 4 | 2 |

| NNX-2RSP-D0.3-L1.5 | 0.5 | 0.1 | 0.5 | 6 | 50 | 4 | 2 |

| NNX-2RSP-D0.3-L2 | 0.5 | 0.1 | 0.5 | 8 | 50 | 4 | 2 |

| NNX-2RSP-D0.3-L3 | 0.5 | 0.1 | 0.5 | 10 | 50 | 4 | 2 |

| NNX-2RSP-D0.3-L4 | 0.6 | 0.02 | 0.6 | 2 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L1 | 0.6 | 0.02 | 0.6 | 3 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L1.5 | 0.6 | 0.02 | 0.6 | 4 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L2 | 0.6 | 0.02 | 0.6 | 5 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L3 | 0.6 | 0.02 | 0.6 | 6 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L4 | 0.6 | 0.02 | 0.6 | 8 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L5 | 0.6 | 0.02 | 0.6 | 10 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L6 | 0.6 | 0.05 | 0.6 | 2 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L1 | 0.6 | 0.05 | 0.6 | 3 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L1.5 | 0.6 | 0.05 | 0.6 | 4 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L2 | 0.6 | 0.05 | 0.6 | 5 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L3 | 0.6 | 0.05 | 0.6 | 6 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L4 | 0.6 | 0.05 | 0.6 | 8 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L5 | 0.6 | 0.05 | 0.6 | 10 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L6 | 0.6 | 0.1 | 0.6 | 2 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L1 | 0.6 | 0.1 | 0.6 | 3 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L1.5 | 0.6 | 0.1 | 0.6 | 4 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L2 | 0.6 | 0.1 | 0.6 | 5 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L3 | 0.6 | 0.1 | 0.6 | 6 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L4 | 0.6 | 0.1 | 0.6 | 8 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L5 | 0.6 | 0.1 | 0.6 | 10 | 50 | 4 | 2 |

| NNX-2RSP-D0.4-L6 | 0.6 | 0.2 | 0.6 | 2 | 50 | 4 | 2 |

| NNX-2RSP-D0.5-L2 | 0.6 | 0.2 | 0.6 | 3 | 50 | 4 | 2 |

| NNX-2RSP-D0.5-L3 | 0.6 | 0.2 | 0.6 | 4 | 50 | 4 | 2 |

| NNX-2RSP-D0.5-L4 | 0.6 | 0.2 | 0.6 | 5 | 50 | 4 | 2 |

| NNX-2RSP-D0.5-L5 | 0.6 | 0.2 | 0.6 | 6 | 50 | 4 | 2 |

| NNX-2RSP-D0.6-L8 | 0.6 | 0.2 | 0.6 | 8 | 50 | 4 | 2 |

| NNX-2RSP-D0.6-L10 | 0.6 | 0.2 | 0.6 | 10 | 50 | 4 | 2 |

| NNX-2RSP-D0.8-L2 | 0.8 | 0.02 | 0.8 | 2 | 50 | 4 | 2 |

| NNX-2RSP-D0.8-L3 | 0.8 | 0.02 | 0.8 | 3 | 50 | 4 | 2 |

| NNX-2RSP-D0.8-L4 | 0.8 | 0.02 | 0.8 | 4 | 50 | 4 | 2 |

| NNX-2RSP-D0.8-L5 | 0.8 | 0.02 | 0.8 | 5 | 50 | 4 | 2 |

| NNX-2RSP-D0.8-L6 | 0.8 | 0.02 | 0.8 | 6 | 50 | 4 | 2 |

| NNX-2RSP-D0.8-L8 | 0.8 | 0.02 | 0.8 | 8 | 50 | 4 | 2 |

| NNX-2RSP-D0.8-L10 | 0.8 | 0.02 | 0.8 | 10 | 50 | 4 | 2 |

| NNX-2RSP-D0.8-L2 | 0.8 | 0.05 | 0.8 | 2 | 50 | 4 | 2 |

| NNX-2RSP-D0.8-L3 | 0.8 | 0.05 | 0.8 | 3 | 50 | 4 | 2 |

| NNX-2RSP-D0.8-L4 | 0.8 | 0.05 | 0.8 | 4 | 50 | 4 | 2 |

| NNX-2RSP-D0.8-L5 | 0.8 | 0.05 | 0.8 | 5 | 50 | 4 | 2 |

| NNX-2RSP-D0.8-L6 | 0.8 | 0.05 | 0.8 | 6 | 50 | 4 | 2 |

| NNX-2RSP-D0.8-L8 | 0.8 | 0.05 | 0.8 | 8 | 50 | 4 | 2 |

| NNX-2RSP-D0.8-L10 | 0.8 | 0.05 | 0.8 | 10 | 50 | 4 | 2 |

| NNX-2RSP-D0.8-L2 | 0.8 | 0.1 | 0.8 | 2 | 50 | 4 | 2 |

| NNX-2RSP-D0.8-L3 | 0.8 | 0.1 | 0.8 | 3 | 50 | 4 | 2 |

| NNX-2RSP-D0.8-L4 | 0.8 | 0.1 | 0.8 | 4 | 50 | 4 | 2 |

| NNX-2RSP-D0.8-L5 | 0.8 | 0.1 | 0.8 | 5 | 50 | 4 | 2 |

| NNX-2RSP-D0.8-L6 | 0.8 | 0.1 | 0.8 | 6 | 50 | 4 | 2 |

| NNX-2RSP-D0.8-L8 | 0.8 | 0.1 | 0.8 | 8 | 50 | 4 | 2 |

| NNX-2RSP-D0.8-L10 | 0.8 | 0.1 | 0.8 | 10 | 50 | 4 | 2 |

| NNX-2RSP-D0.8-L2 | 0.8 | 0.2 | 0.8 | 2 | 50 | 4 | 2 |

| NNX-2RSP-D0.8-L3 | 0.8 | 0.2 | 0.8 | 3 | 50 | 4 | 2 |

| NNX-2RSP-D0.8-L4 | 0.8 | 0.2 | 0.8 | 4 | 50 | 4 | 2 |

| NNX-2RSP-D0.8-L5 | 0.8 | 0.2 | 0.8 | 5 | 50 | 4 | 2 |

| NNX-2RSP-D0.8-L6 | 0.8 | 0.2 | 0.8 | 6 | 50 | 4 | 2 |

| NNX-2RSP-D0.8-L8 | 0.8 | 0.2 | 0.8 | 8 | 50 | 4 | 2 |

| NNX-2RSP-D0.8-L10 | 0.8 | 0.2 | 0.8 | 10 | 50 | 4 | 2 |

| Værktøjsserie | Diameter | Radius | Hjørne radius | Fløjte længde | Effektiv længde | Samlet længde | Shank Dia | |||

| D | R | CR | Lc | L1 | L | d | ||||

| NNX hårdmetal endefræsere til kobberelektrode | D0,1~D0,9 | 0 -0,005 | R0,05~R2 | /-0,005 | CR0,05~CR0,5 | /-0,005 | 0 0.3 | 0 0.3 | 0.5 -0,5 | h5 |

| D1~D3,5 | 0 -0,005 | |||||||||

| D4~D10 | -0,003 -0,015 | R3~R5 | /-0,005 | CR1.0~CR3.0 | /-0,008 | 0 0.5 | 0 0.5 | |||

| D12~D20 | -0,003 -0,018 | R6~R10 | /-0,008 | |||||||

NNX-2RSP-seriens produkter tilbyder en bred vifte af størrelser, der dækker værktøjsdiametre fra 0,2 mm til 0,8 mm, og opnår en række kombinationer i klingelængde, klingediameter og filetradius. Uanset om det er krav til ultrapræcisionsbearbejdning eller specifikke krav til dybdeskæring, kan denne serie give fleksibel matchning for at opfylde højpræcisionsmuligheder i forskellige bearbejdningsscenarier.

Det unikke dybe rillede rundnæsedesign er specielt designet til finbearbejdning af kobberelektroder, hvilket optimerer skærebelastningsfordelingen og gør det muligt for værktøjet at bevare stabiliteten på et lille rum. 30° spiralvinklen sikrer jævn spånfjernelse og reducerer varme og værktøjsslitage forårsaget af spånophobning under bearbejdning. Kombineret med mikrodiameteregenskaberne kan den opnå fremragende ydeevne i et højpræcisionsbearbejdningsmiljø.

Hele serien bruger (0,2μm) ultrafine partikelsubstrater med den nyeste DLC-belægningsteknologi, hvilket giver værktøjet en ultra-lav friktionskoefficient og fremragende slidstyrke, hvilket i høj grad forbedrer bearbejdningens levetid. Med præcisionsslibningsprocessen når skærekantens skarphed det yderste. Det overordnede design fokuserer på kobberelektrodens spejlbearbejdningsydelse for at opnå mere effektiv og stabil mikrofinish.

Virksomhedsetablering

Medarbejdere

Changzhou Maton Tools Co.,Ltd. is located in the economically developed Yangtze River Delta region.The factory is located in XixiashuHigh-tech Development Zone,a well-known tool town in China. We are 2 fløjte Mlicro diameter dyb rille rund næse kobber elektrode bearbejdning endefræsere Suppliers.

Magotantools take the ISO9001 quality system as the standard,under the guidanceof the business philosophy of"zero defect in products"and"zero distance in service",based on the spirit of"integrity","unity"and"exploita- tion",and follow a fair and just company style for management.Product production adopts five-axisand six-axis CNC grinding and machining centers from Germany,Switzerland,Japan,etc.,and is equipped with high-precision testing equipment such as Germany,Japan,and China,so as to meet the needs of production with high quality and quantity.

The company continuously develops various high-performance CNC tools, and has won various national awards. Professional 2 fløjte Mlicro diameter dyb rille rund næse kobber elektrode bearbejdning endefræsere Factory. More than 10 patents,the company's products are mainly used in the defense industry, aerospace industry,automotive industry,electronic products and molds and other fields.

The company's various products are recognized and favored by well-known domestic companies.With infinite technology,infinite creation,and pursuit of excellence,Magotan tools will write future prosperity and dreams with more extraordinary confidence and high-quality quality.

Vi svarer dig inden for 12 timer efter at have modtaget henvendelsen på hverdage.

Vi er producenter, vi producerer og sælger selv.

We mainly produce tungsten steel milling cutters, drill bits and other hard alloy tools. Professional 2 fløjte Mlicro diameter dyb rille rund næse kobber elektrode bearbejdning endefræsere Suppliers.

Vores produkter dækker næsten hele formindustrien, forsvarsindustrien, rumfartsindustrien, bilindustrien, elektroniske produkter og andre områder.

Yes, our main focus is on customized products. We develop and produce products based on the drawings or samples provided by customers. Custom 2 fløjte Mlicro diameter dyb rille rund næse kobber elektrode bearbejdning endefræsere.

We have over 30 units of WALTER from Germany, Makino from Japan, ROLLMATIC from Switzerland, and TTB from Switzerland, with an annual output value of 80 million RMB. We are 2 fløjte Mlicro diameter dyb rille rund næse kobber elektrode bearbejdning endefræsere Factory

For det første udfører vi efter hver proces tilsvarende inspektioner. For det endelige produkt vil vi udføre 100 % fuld inspektion i henhold til kundens krav og internationale standarder;

Så har vi det avancerede og komplette testudstyr i topklasse i branchen, såsom spektralanalysatorer, metallografiske mikroskoper osv., som kan sikre stabiliteten og konsistensen af skærende værktøjer, samtidig med at kundernes højpræcisionstestkrav til skærende værktøjer opfyldes.

Når du citerer, vil vi bekræfte transaktionsmetoden, FOB, CIF, CNF eller andre muligheder med dig. Når vi producerer i løs vægt, foretager vi normalt 30 % forudbetaling først, og betaler derefter restbeløbet ved fremvisning af konnossementet. Vi bruger for det meste T/T som betalingsmetode, men L/C er også acceptabelt.